|

包裝機密封顎壓

Measure the pressure distribution between packaging machine sealing jaws and bars.

測量包裝機密封顎與桿之間的壓力分布。

Pressure Measurement Improves Packaging Machine Sealing Jaws Performance

壓力測量提高了包裝機的密封性能

Challenge

挑戰(zhàn)

A poor quality seal produced by a packaging machine can result in large quantities of product waste for a manufacturer. This can be a result of uneven bars, low forces or worn parts in the clamp sealing assembly.

由一臺包裝機生產(chǎn)的一個質量低劣的密封件,可能會導致大量的產(chǎn)品浪費,為制造商。這可能是由于不均勻的酒吧,低力量或磨損的零件在鉗位密封組件。

Solution

解決方案

The I-Scan® system has been utilized in packaging applications to help troubleshoot these mechanical problems. By adjusting the sealing forces before the start of a production run, large amounts of product waste can be avoided. The I-Scan® pressure mapping system can be used to inspect worn parts, set up new machines, and improve overall quality control in the production area. It can also be used as a research and development tool to design improved sealing machines.

掃描®系統(tǒng)已經(jīng)在包裝領域的應用來幫助解決這些力學問題。通過在生產(chǎn)運行開始前調整密封力,可以避免大量的產(chǎn)品浪費。掃描®壓力映射系統(tǒng)可以用來檢查磨損的部件,建立了新的機器,提高生產(chǎn)領域的全面質量控制。它也可以作為一個研究和開發(fā)工具,設計改進的密封機。

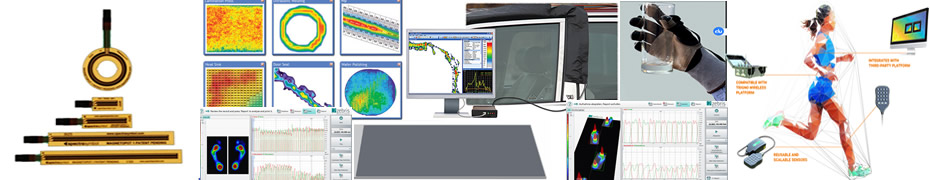

Tekscan’s patented, thin-film sensors are available in different shapes, are reusable, and provide accurate pressure readings. With the help of our highly qualified sales and engineering support team, each system may be configured to meet your specific needs.

Tekscan的專利,薄膜傳感器有不同的形狀,可重復使用,并提供準確的壓力讀數(shù)。在我們的高素質的銷售和工程支持團隊的幫助下,每一個系統(tǒng)可以配置,以滿足您的特定需求。

Before and after pressure output of sealing jaws. Before test taken showing weak pressures on the outside (left). Adjustments are made, a second test is taken confirming a more even seal (right).

密封顎壓力輸出前后。在測試之前,顯示出在外部的弱壓力(左)。調整,二次測試是采取了更均勻的密封(右)。

Before and after pressure output of sealing jaws. Before test taken showing weak pressures on the outside (left). Adjustments are made, a second test is taken confirming a more even seal (right).

密封顎壓力輸出前后。在測試之前,顯示出在外部的弱壓力(左)。調整,二次測試是采取了更均勻的密封(右)。

Pressure Measurement Sealing Applications

壓力測量密封應用

Identify worn parts, low forces, and uneven sealing bars

確定磨損的部件,低的力量,和不均勻的密封條

R&D for new machine design

新機器設計的研發(fā)

Before and after adjustment comparison

調整前后比較

Machine to machine comparison

機器比較

Reliability and validation testing

可靠性和驗證測試

Benefits of using pressure measurement for machine setup

機械安裝使用壓力測量的好處

Reduce machine set-up time

減少機器設置時間

Minimize product waste

盡量減少產(chǎn)品浪費

Identify low yield machines

識別低產(chǎn)機

Increase yield in manufacturing

提高產(chǎn)量

|